Paushak’s R&D lab is where molecules are first developed and validated. Our expert scientists, with deep synthesis expertise, play a critical role in molecule creation and refinement. Backed by advanced lab-scale infrastructure and rigorous impurity profiling, we ensure every process meets the highest standards of quality from the start.

Safe handling of phosgene reactions for complex intermediates.

Tailored services for specific requirements, expertise in hazardous chemistry and organic synthesis.

The Kilo Lab serves as the critical gateway to commercial production. At this stage, we collect data and fine-tune processes to ensure efficiency, safety, and regulatory compliance before moving to full-scale manufacturing.

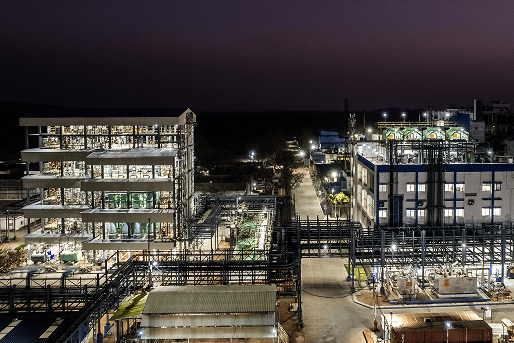

As India’s largest phosgene based specialty chemical manufacturer, Paushak’s state-of-the-art manufacturing facility is designed for scalability and compliance. With fully automated DCS-controlled plants, we efficiently manage complex processing needs across multiple applications while ensuring reliable chemical production.

With over 45 years of expertise in handling Phosgene and its derivatives, our facility integrates the latest safety infrastructure, including:

We have dedicated effluent treatment and waste management systems, including:

Our facility consists of versatile multi-purpose plants capable of handling:

| Equipment | Description | Capacity |

|---|---|---|

| SS-316 Reactors | Jacketed / Limpeted | 1KL to 10 KL |

| MSGL Reactors | Jacketed | 0.63 KL to 10 KL |

| Distillation Systems | MSGL/SS316 | - |

| Agitated Nutsche Filters | SS316 | 2.5 KL |

| Centrifuges | SS316 Halar coated | - |

| Agitated Thin Film Evaporator | SS-316 | - |

| Scrubber Systems | Alkaline scrubber | Each plant is equipped with a scrubber system to handle adequate load. |

Our production process is backed by a dedicated quality control laboratory equipped with:

Paushak’s large-scale production is built on its expertise in complex chemical synthesis, including: